Processing

Processing

Bano Food Enterprises: Expert Processing

At Bano Food Enterprises, we take pride in our meticulous processing techniques to ensure the highest quality products reach your table.

Our state-of-the-art facilities are equipped with advanced technology to clean, sort, and package our rice and organic foods to perfection.

Every grain undergoes rigorous quality control measures to maintain its purity and nutritional value. From husking to polishing, and final

packaging, each step of our processing is designed to preserve the natural goodness and ensure the utmost satisfaction of our customers.

Trust Bano Food Enterprises for excellence in every bite.

Bano Food Enterprises:

Expert Processing

At Bano Food Enterprises, we take pride in our meticulous processing techniques to ensure the highest quality products reach your table. Our state-of-the-art facilities are equipped with advanced technology to clean, sort, and package our rice and organic foods to perfection. Every grain undergoes rigorous quality control measures to maintain its purity and nutritional value. From husking to polishing, and final packaging, each step of our processing is designed to preserve the natural goodness and ensure the utmost satisfaction of our customers. Trust Bano Food Enterprises for excellence in every bite.

Choosing the Finest Paddy

Every grain we offer is meticulously selected for its exceptional quality, texture, and authentic flavor. Our expert selectors ensure that each grain meets our stringent standards, guaranteeing optimal yield, precise grain length, and ideal cooking characteristics. Enjoy the finest quality rice with every serving.

Husking Process

The carefully selected paddy undergoes a gradual moisture reduction, employing both modern and traditional techniques to achieve the optimal moisture content for husking. Once this ideal state is reached, the outer husks are gently removed, unveiling the pure rice grains. This process ensures minimal breakage and preserves the integrity of the germ and bran layers, maintaining the rice’s natural nutrition and quality.

Cleaning Process

Every grain we offer is meticulously selected for its exceptional quality, texture, and authentic flavor. Our expert selectors ensure that each grain meets our stringent standards, guaranteeing optimal yield, precise grain length, and ideal cooking characteristics. Enjoy the finest quality rice with every serving.

Whitening & Polishing

To achieve the premium quality of our rice products, we have invested in state-of-the-art machinery and mist polishers. These advanced tools ensure that our rice grains have a pristine white and pearly appearance, reflecting their superior quality. Our meticulous whitening and polishing processes enhance the visual appeal and maintain the nutritional integrity of our rice, offering you the best in both looks and taste.

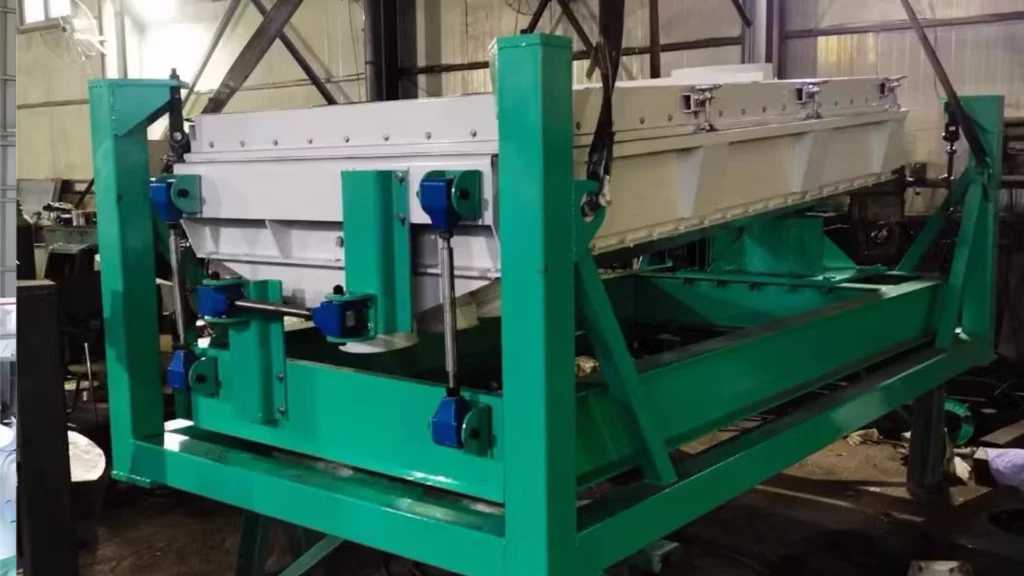

Grading Process

Every rice grain undergoes meticulous grading based on its length and thickness to ensure only the best make it to your table. This process removes underdeveloped, malnourished, desiccated, or broken grains. We utilize advanced grading machinery, including indented cylinders and plan-sifters, to achieve consistent uniformity in our rice products. This precision ensures that you receive only the finest quality grains, every time.

Color Sorting

Using advanced CCD technology, we perform high-resolution optical inspections on each and every rice kernel. Our state-of-the-art TAIHO Color Sorter Machine effectively eliminates predominantly discolored and chalky kernels, ensuring only healthy, high-quality grains make it to your table. This meticulous process guarantees the purity and visual appeal of our rice, offering you a superior product.

Packaging

The integrity of our products greatly depends on their packaging. At Bano Food Enterprises, we prioritize our customers’ packaging requirements and provide tailored advice to suit their target audience. Equipped with advanced packing machines, we ensure accurate weight and uniform packing for easy handling and extended shelf life. Understanding that packaging plays a crucial role in sales, we always offer the best possible packaging types and designs to leave a lasting impression on the final consumer.

Warehousing

Proper aging of Basmati rice at optimal temperatures in a safe, dry environment is crucial to achieving the desired yield and minimizing breakage or wastage during processing. At Bano Food Enterprises, we ensure that de-husked paddy is securely stored in our warehouses, adhering to a strict first-in, first-out scheme. We conduct regular inspections to maintain high quality and food safety standards, ensuring that our rice retains its superior quality throughout the storage period.

Shipment

At Bano Food Enterprises, we take our shipment schedules very seriously. We meticulously track all shipments until they reach their final destination and ultimately the buyer. We prioritize selecting reliable and credible shipping channels to avoid any hassles or setbacks, ensuring a smooth and timely delivery process. Our commitment to excellence in logistics guarantees that your orders arrive safely and punctually, maintaining the integrity and quality of our products.

Bano Food Enterprises: Meeting Global Demand with Excellence

At Bano Food Enterprises, we pride ourselves on a business model that caters to the needs of our global clientele. Our dedicated customer service team is always ready to provide comprehensive information, exceptional services, and reliable support to address every customer’s query. Experience the commitment and quality that define our brand.